Technology

SurfCon® Technology Introduction

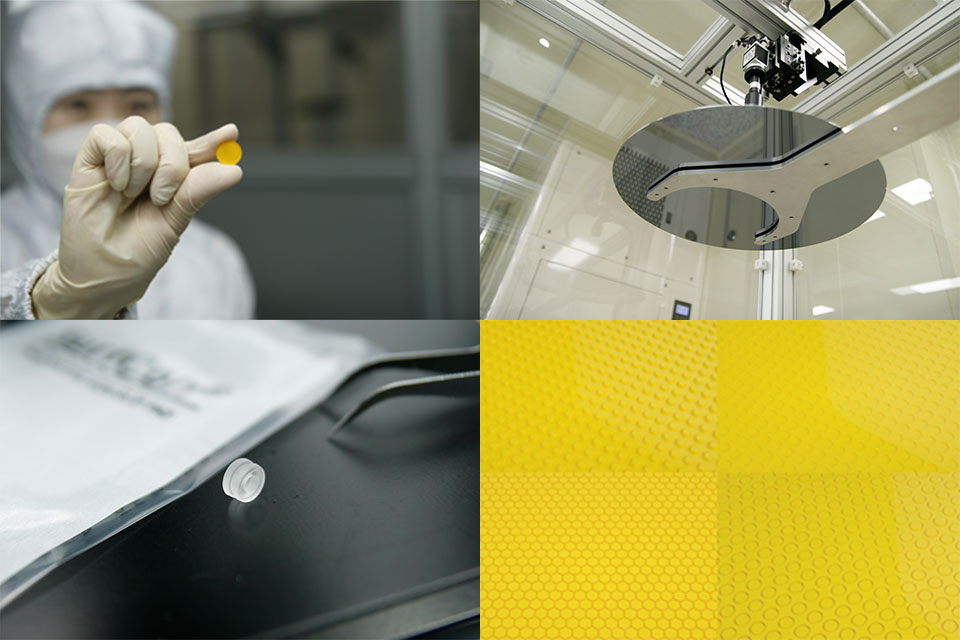

Key Technology

Directional cross-linking technology and micro patterning technology enables to control the direction of adhesion force and provide enough horizontal grip but popping free when substrate is separated from the pad.

SurfCon® is inspired by

Advanced Polymer Engineering

SurfCon® is customized by

Precision Molding & Cutting

SurfCon® is designed by

Micro Patterning Technology

SurfCon® is manufactured by

Class 10 Quality Control

Benefit for Customer

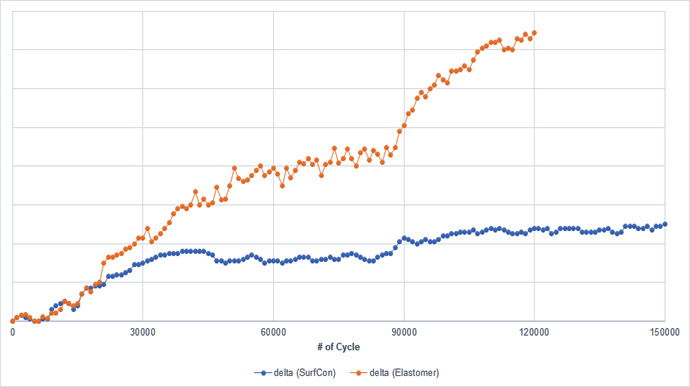

Cycle Test Comparison ,

R-axis

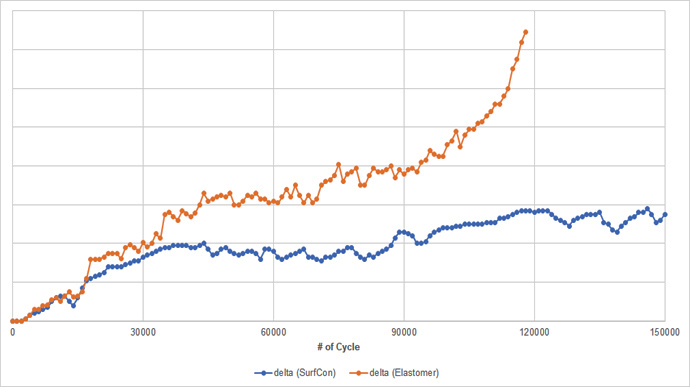

Cycle Test Comparison ,

T-axis

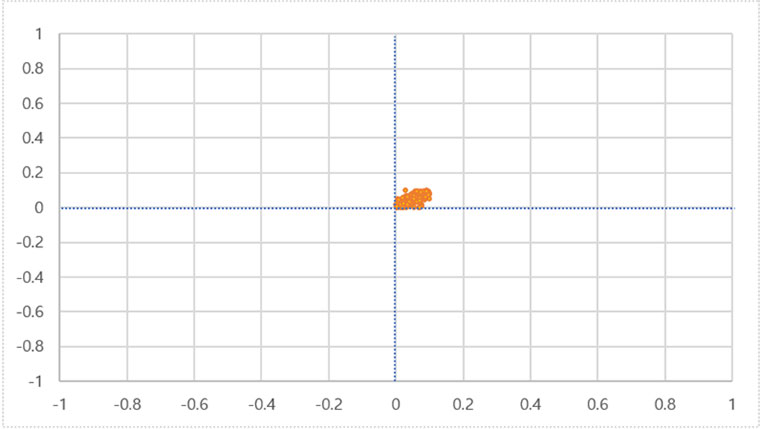

Wafer slippage comparison by wafer cycling test

Misalignment by Popping (SurfCon®)

Misalignment by Popping (Soft Elastomer Pad)

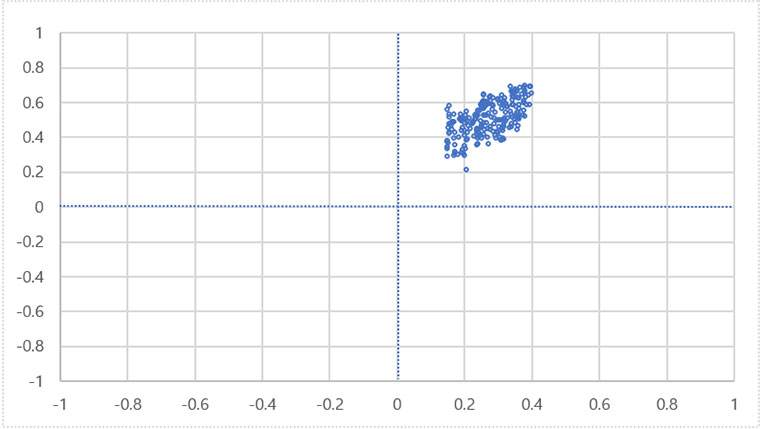

Optical alignment key measurement data (X,Y) with 1,000 cycles