Applications

Serviceable Application of SurfCon®

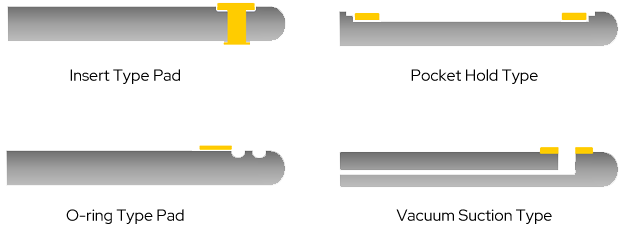

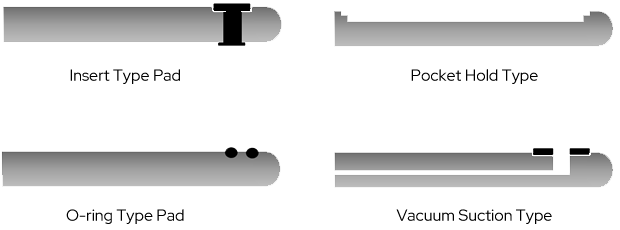

by Type of End Effector

- Replace Conventional Elastomer Pads with SurfCon®

- Attach SurfCon® on Pocket Hold Type End Effector

- Replace Vacuum Suction Pad with SurfCon®

- Attach SurfCon® on Edge Grip Type End Effector

- Replace Bernoulli Pad with SurfCon®

by Type of Chronic Issues

- Substrate sliding and misalignment

- Popping during pick and place

- Low throughput

- Backside contamination

- Short lifetime of conventional elastomer pads

- Electrostatic Discharge

- High temperature (~300℃)

- Different handling methods for ATM vs. VTM

by Type of Substrate

- Normal Si Wafer

- TAIKO Wafer

- Warped Wafer

- Glass Wafer

- Sapphire Wafer

- LT Wafer

- SiC Wafer

- Ultra Thin Wafer

- Ring Framed Wafer

- Display Glass

- Photovoltaic Cell

| Blade Type | Environment | Temp | Chronic Issues of Conventional Handling Method |

|---|---|---|---|

| Vacuum Suction with Elastomer Pad | ATM | Room Temp | Backside mark, Sliding, and High Cost |

| Pocket Type | ATM | Room Temp | Natural sliding and Collision, Chipping and Particles |

| Edge Grip | ATM | Room Temp | Substrate damage by strong grip, Chipping and Particles |

|

Passive (Elastomer Pad) |

ATM | Room Temp | Easy Worn-out, Wafer Misalignment and Sliding by Weak Adhesion Force, Short Lifetime (3~4 months), Particles, Not able to use at ~300 degree C |

| Pocket Type | Vacuum | Room Temp | Natural sliding and Collision, Chipping and Particles |

|

Passive (Elastomer Pad) |

Vacuum | Room Temp | Easy Worn-out, Wafer Misalignment and Sliding by Weak Adhesion Force, Short Lifetime (3~4 months), Particles, Not able to use at ~300 degree C |

|

Pocket Type (Ceramic) |

ATM | High Temp | Natural sliding and Collision, Chipping and Particles |

|

Pocket Type (Ceramic) |

Vacuum | High Temp | Natural sliding and Collision, Chipping and Particles |

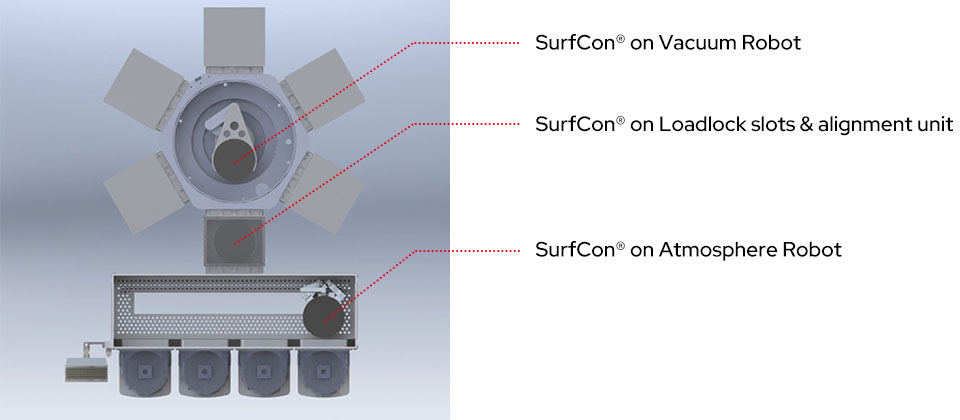

Example of SurfCon® for Substrate Handling

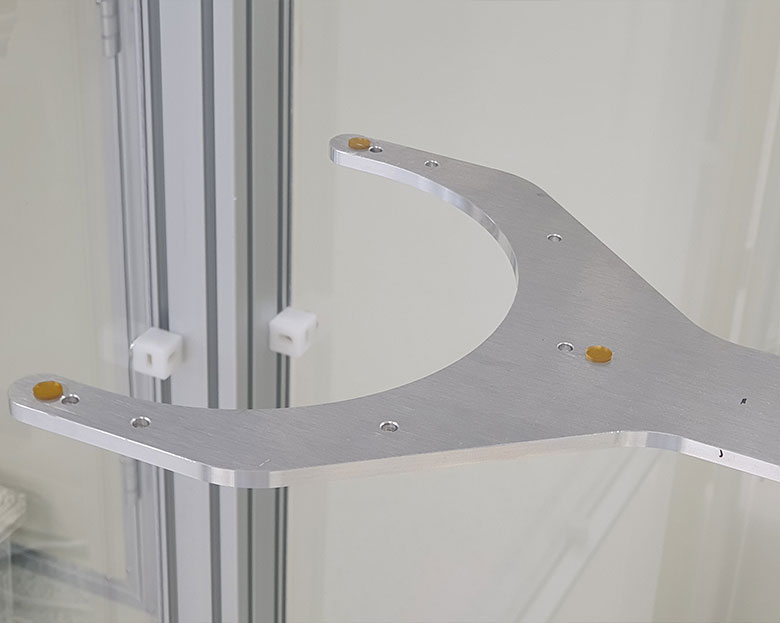

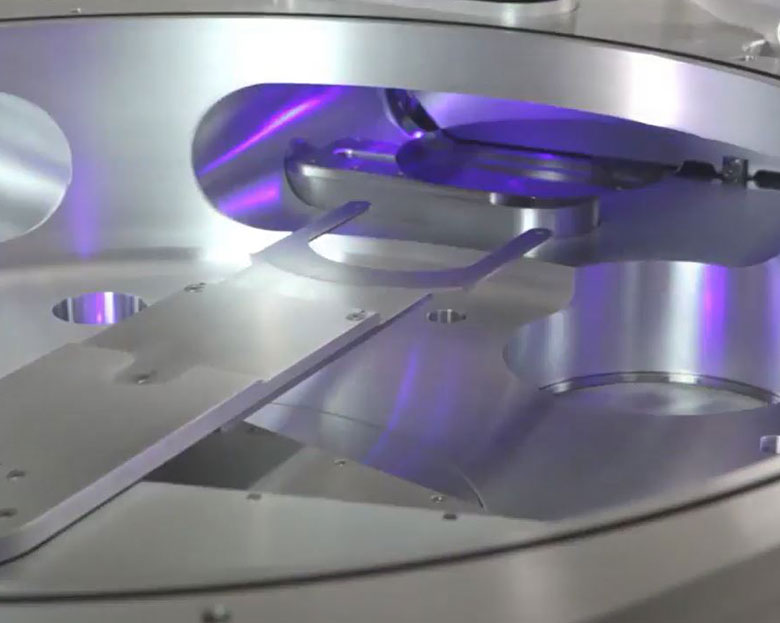

SurfCon® on ATM Robot End Effector

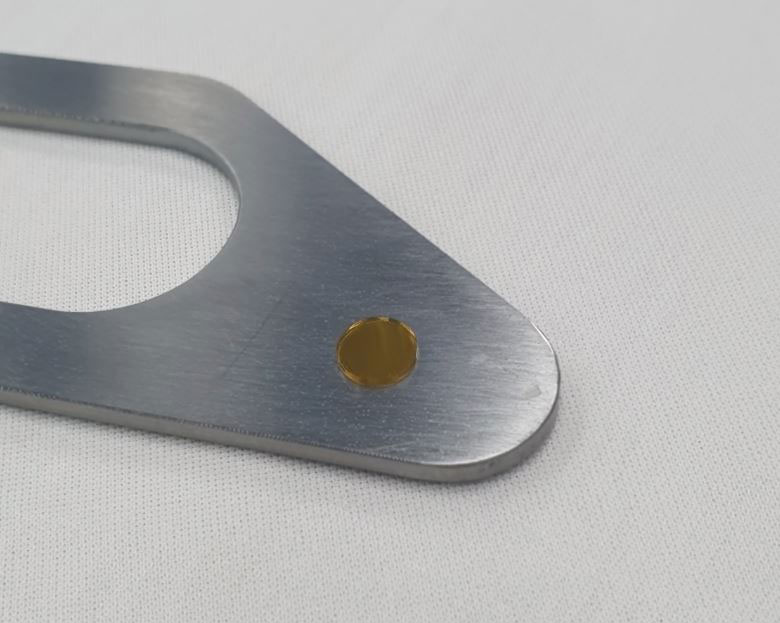

SurfCon® on Passive Type End Effector

SurfCon® on VTM Robot End Effector

How to use SurfCon® on current method

Conventional Style End Effector